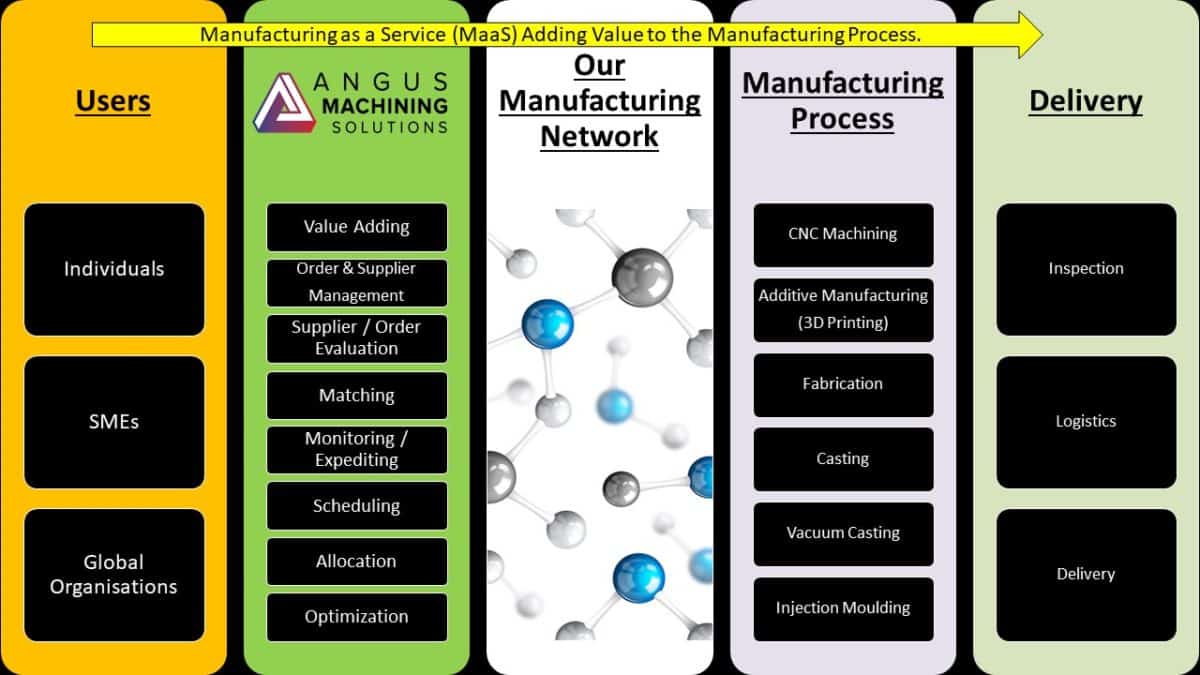

Who needs their own manufacturing facility, when Angus Machining Solutions offer Machining / Manufacturing as a Service (MaaS)

Angus Machining Solutions Ltd recognise some companies don’t always have the resources or the experience to manage the machining / manufacturing process internally, so give support to these companies with their machining & manufacturing as a service. (MaaS)

Contract manufacturing has always been a service, but Angus Machining Solutions is changing the way products are being manufactured. Our customers submit their requirements and projects and we review these and provide a fast, precise quotes from our approved network of suppliers. When an order is then placed for a part, Angus Machining Solutions will route the order to a suitable supplier and manage it efficiently to fulfil the requirements based on workload, materials, available capacity and location.

Five argument for using our MaaS,

- We work closely with customers and suppliers to find new ways to add value.

- It makes our customers more competitive by cutting costs and making processes more efficient without having to invest in large Capex assets, thus releasing capital for investment in R&D, Marketing & Sales.

- Provides accessibility for a wider variety of resources and technologies.

- Encourages collaboration and creates a less wasteful sharing-based economy, where everyone stands to benefit.

- Our customers receive experience and not just the end product.

Our Machining & Manufacturing service allows companies to free up valuable internal resources by having us handle this for them and in most cases reducing their sourcing costs.

With many years of machining and manufacturing experience, you can hand over your machining requirements with confidence knowing these are being met through our sourcing process. We manage the machining & manufacturing process through our large network of key partners here in Scotland, The UK, Europe and specially selected key suppliers in China & Vietnam.

Our services are being used by:-

- Start-up companies who have been focused on the design of their product and are now ready to move to manufacturing. They however, don’t have the resources or sufficient machining knowledge to progress this process in an efficient or effective manner. By using Angus Machining Solutions, it allows them to focus on their key strengths and have the manufacturing / machining of their product managed on their behalf.

- SME companies, who don’t want to be burdened with establishing the manufacturing / machining capabilities. They want this process managed on their behalf.

- Larger organisations use Angus Machining Solutions to manage the machining and manufacturing process on specific projects. Preventing additional short term resources being employed to manage short term projects / demand. It also allows them to use their internal resources to focus on other aspects of the supply chain.

Benefits of our MaaS:-

- Support / Management of your machining and manufacturing needs

- This reducing administrative and manufacturing costs

- Instant experience & knowledge brought in to your business (No recruitment)

- Help in identifying appropriate suppliers

- Releasing internal resources to focus on other aspects of their business

- Helping in the development and strengthening of their supply chain

Services

Ad Hoc

One off sourcing, where we can have your part, machined / manufactured to your specification. We manage the machining / manufacturing through our supplier network and supply the part directly to you. You don’t have anything to organise or manage.

Project Management

We can manage a specific machining / manufacturing project for you. We work with you and any suppliers you may already have and help identify new suppliers where needed. We then manage the full or just specific aspects of the machining / manufacturing process:- Supplier Identification – Supplier Audits – Order Placement – Manufacturing Monitoring – Expediting – Final Inspection – Delivery – Supplier Integration. Allowing you to have specific projects managed on your behalf. Releasing internal resources to work on other projects/ aspects of the business.

Supplier Development

The main objective is to identify new suppliers and have them ready to be integrated in to your Approved Vendor List (AVL) and supply chain. We achieve this by working closely with you and the newly identified suppliers. We have these suppliers audited to meet your quality requirements, manage the first manufacturing orders through them and then have them ready to be added to your AVL

The MaaS Process